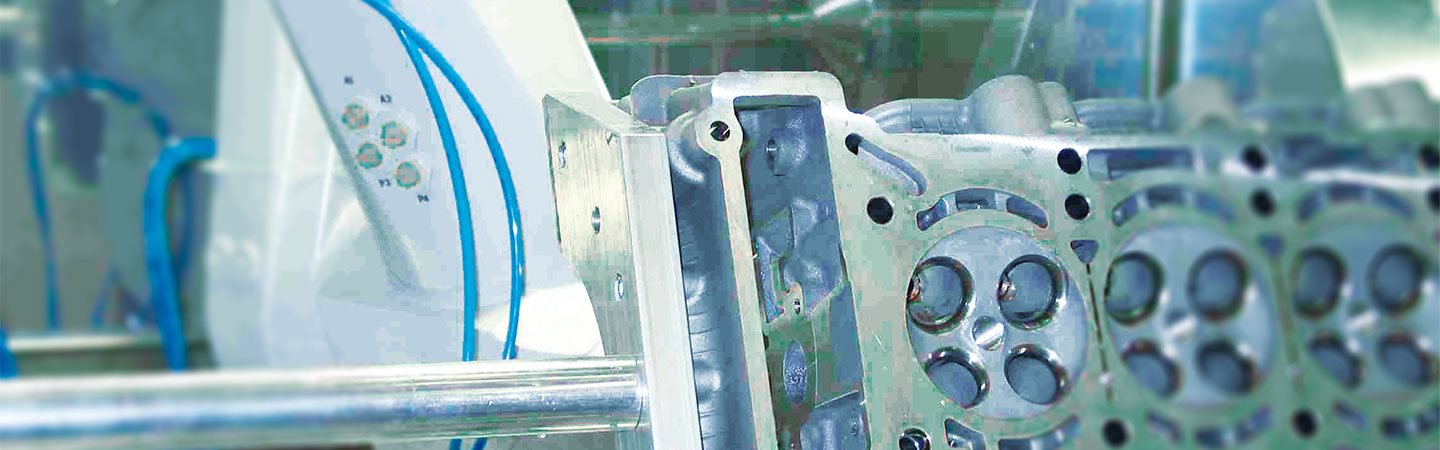

Component cleaning as added value

Superior quality in manufacturing is absolutely dependent on the technical cleanliness of semi-finished products, components and their functional surfaces, as well as the conditions under which production takes place. System components are shrinking in size even as they become technically more complex. Cleaning processes, as a result, are becoming increasinglyelaborate and costly. Residual contaminants on components not only impair the functionalityof technical systems; they also increase the rate of rejected production output, which pushesup manufacturing costs. Ensuring components are clean therefore adds substantial value tothe manufacture of components and assemblies. The need to make better use of availablecleaning technologies is not merely a consequence of cost considerations, however, as is readily seen through the enforcement of increasingly stringent legislation to protect the environment – in itself a response to a growing awareness of environmental issues.

Integrating cleaning into the manufacturing process

Industry often views the cleaning of components as a necessary evil. Manufacturers are frequently tempted to simply tack cleaning on to the end of existing production lines, if this is at all possible, rather than integrating cleaning into a comprehensive view of the entire production process. Such integration, however, is imperative to maintaining both competitiveness and exacting quality standards, especially when profit margins are low. Fraunhofer-Business Area Cleaning has generated various ideas, concepts and solutions that allow cleaning and production to be viewed as a closely matched entity, one that makes cleaning a welcomed and useful contributor to added value. Our approach is divided into three phases: A look at ways to avoid cleaning, is followed by possible approaches to minimizing the cleaning required, and finally how to improve the effectiveness of cleaning processes.

Main areas of focus

• Integrating cleaning intoproduction

• Automation of cleaningprocesses

• Cleaning technologies

• Analysis

Fraunhofer-Business Area Cleaning

Fraunhofer-Business Area Cleaning